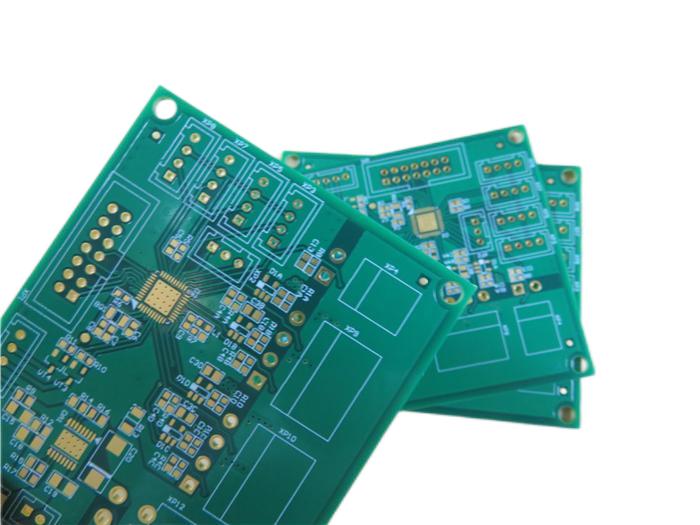

Advanced 6-Layer Hybrid PCBs with RO4003C and FR-4 for High-Frequency Applications

(Custom PCBs are tailored products; the images and specifications provided are for reference only.)

Introduction of RO4003C

Rogers RO4003C materials are proprietary woven glass reinforced hydrocarbon/ceramics that combine the electrical performance of PTFE/woven glass with the manufacturability of epoxy/glass. These laminates provide tight control over the dielectric constant (Dk) and exhibit low loss, utilizing standard epoxy/glass processing methods at a fraction of the cost of conventional microwave laminates. Unlike PTFE-based materials, RO4003C does not require special through-hole treatments or handling procedures.

RO4003C materials are non-brominated and are not rated UL 94 V-0.

Features of RO4003C

Dielectric Constant: DK 3.38 ± 0.05 at 10GHz

Dissipation Factor: 0.0027 at 10GHz

Thermal Conductivity: 0.71 W/m/°K

Thermal Coefficient of Dielectric Constant: +40 ppm/°C (ranging -50°C to 150°C)

CTE Matched to Copper: X-axis 11 ppm/°C, Y-axis 14 ppm/°C

Low Z-axis CTE: 46 ppm/°C

Tg: >280°C

Low Moisture Absorption: 0.06%

Basic PCB Specifications

| Specification | Details |

|---|---|

| Base Material | RO4003C and FR-4 mixed |

| Layer Count | 6 layers |

| Board Dimensions | 83.50mm x 66mm (1 PCS), ± 0.15mm |

| Minimum Trace/Space | 4/4 mils |

| Minimum Hole Size | 0.2mm |

| Blind and Buried Vias | Top layer to inner layer 1 (L2), inner layer 2 to inner layer 3 (L3-L4) |

| Finished Board Thickness | 1.1mm |

| Finished Copper Weight | 1oz (1.4 mils) inner/outer layers |

| Via Plating Thickness | 20 µm |

| Surface Finish | Immersion Gold |

| Top Silkscreen | White |

| Bottom Silkscreen | No |

| Top Solder Mask | Matt Green |

| Bottom Solder Mask | Matt Green |

| Impedance Control | 50 ohm on 4mil / 4mil traces/gaps, top layer |

| Print Series Number | Included |

| Via Filling | 0.2mm vias filled and capped |

| Electrical Testing | 100% electrical test prior to shipment |

PCB Stack-Up (6-Layer Rigid PCB)

| Layer | Material | Thickness |

|---|---|---|

| Copper Layer 1 | Copper | 35 µm |

| Copper Layer 2 | RO4003C | 0.305 mm (12 mil) |

| Copper Layer 3 | Copper | 35 µm |

| Prepreg Bondply | 1080 RC63% | 0.0644 mm (2.5 mil) |

| Copper Layer 4 | Copper | 35 µm |

| FR-4 | Core | 0.076 - 0.203 mm (3 mil) |

| Copper Layer 5 | Copper | 35 µm |

| Prepreg Bondply | 1080 RC63% | 0.0644 mm (2.5 mil) |

| Copper Layer 6 | Copper | 35 µm |

| RO4003C | Core | 0.305 mm (12 mil) |

PCB Statistics:

Components: 51

Total Pads: 82

Through Hole Pads: 53

Top SMT Pads: 29

Bottom SMT Pads: 0

Vias: 49

Nets: 6

Artwork and Standards Information

Type of Artwork Supplied: Gerber RS-274-X

Accepted Standard: IPC-Class-2

Availability: Worldwide

Typical Applications

Commercial airline broadband antennas

Microstrip and stripline circuits

Millimeter wave applications

Radar systems

Guidance systems

Point-to-point digital radio antennas