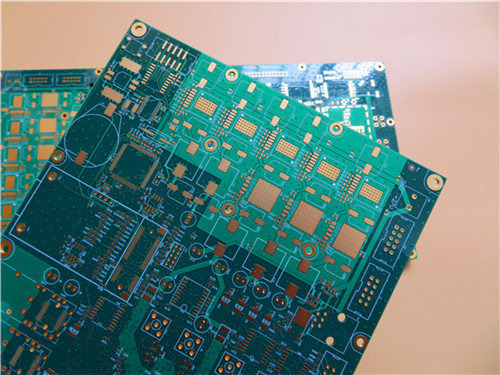

IT-180 10-Layer High Temperature HDI PCB with Immersion Gold and 100 Ohm Impedance

(All PCBs are custom-manufactured. Reference images and parameters may vary based on your design requirements.)

Brief Introduction

This 10-layer printed circuit board is constructed using ITEQ’s IT-180 FR-4 Tg170 substrate, specifically designed for PLC control applications. It has a thickness of 2.0 mm, featuring a white silkscreen on a green solder mask and immersion gold coating on the pads. The board is supplied as a single unit and incorporates a high-density interconnection configuration with blind vias from layers L1 to L3 and L7 to L10, as well as buried vias from L3 to L7. A 100 ohm impedance is controlled on the top layer with trace/gap dimensions of 4 mil/5 mil. The boards are fabricated according to IPC 6012 Class 2 standards using the provided Gerber data, with each set of 20 boards vacuum packed for shipment.

PCB Specifications

| Item | Description | Value | |

| Layer count | 10 layer PCB | 10 layer board | |

| Board type | Multilayer pcb | Multilayer pcb board | |

| Board size | 168.38 x 273.34mm=1up | 168.38 x 273.34mm=1up | |

| Laminate | Laminate Type | FR4 IT-180A | |

| Supplier | ITEQ | ||

| Tg | TG ≧170 | ||

| Finished thickness | 2.0+/-10% MM | ||

| Plating Thickness | PTH Cu thickness | >20 um | |

| Inner layer Cu Thickness | 1/1 OZ | ||

| Surface Cu thickness | 35 um | ||

| Solder Mask | Material type | LP-4G G-05 | |

| Supplier | Nan Ya | ||

| Color | Green | ||

| Single / both sides | Both Sides | ||

| S/M thickness | >=10.0 um | ||

| 3M tape test | NO Peel Off | ||

| Legend | Material type | S-380W | |

| Supplier | Tai yo | ||

| Color | White | ||

| Location | Both Sides | ||

| 3M tape test | No peel off | ||

| Circuit | Trace Width (mm) | 0.203+/-20%mm | |

| Spacing (mm) | 0.203+/- 20%mm | ||

| Identification | UL mark | 94V-0 | |

| Date code | 1025 | ||

| Mark location | CS | ||

| Surface Treatment | ENIG | Nickel | 100u'' |

| Gold | ≧2u'' | ||

| Reliabilty Tests | Thermal shock test | 288±5℃, 10sec ,3 cycles | |

| solder abllity test | 245±5℃ | ||

| Function | Electrioal Test | 233+/-5℃ | |

| Standard | IPC_6012C CLASS 2 | 100% | |

| Appearance | Visual inspection | 100% | |

| warp and twist | <= 0.75% | ||

| Vias | Through holes | L1-L10 | |

| Blind vias & Buried vias | L1-L3, L7-L10, L3-L7 | ||

| Drill table (mm) | No | PTH/NPTH | Size |

| 1 | Y | 0.500*1.00+/-0.075 | |

| 2 | Y | 0.508+/-0.075 | |

| 3 | Y | 0.610+/-0.075 | |

| 4 | N | 0.700+/-0.075 | |

| 5 | Y | 0.711+/-0.075 | |

| 6 | Y | 0.914+/-0.075 | |

| 7 | N | 1.118+/-0.075 | |

| 8 | N | 1.219+/-0.075 | |

| 9 | N | 1.524+/-0.075 | |

| 10 | N | 1.600+/-0.075 | |

| 11 | Y | 2.540+/-0.075 | |

| 12 | Y | 2.997+/-0.075 | |

| 13 | N | 3.500+/-0.075 | |

Typical Applications

CCTV Security: Suitable for security camera systems.

Wireless G Router: Designed for wireless communication devices.

Programmable Controllers: Ideal for automation applications.

Automotive: Used in engine room ECU systems.

Multilayer and HDI PCB: Supports complex circuit designs.

Backplanes: Suitable for high-performance backplane applications.

Data Storage: Designed for data storage solutions.

Server and Networking: Meets the demands of server and networking equipment.

Telecommunications: Ideal for telecom devices.

Our Advantages

Proactive Engineering Design: Prevents issues during pre-production.

Certifications: ISO9001, ISO14001, ISO13485, IATF 16949, UL certified.

Robust PCB Capabilities: Supports R&D, sales, and marketing efforts.

Any Layer HDI PCBs: Flexible production options available.

Workshop Size: 16,000㎡ facility with a monthly output of 30,000㎡.

Diverse PCB Types: Capable of producing 8,000 types of PCBs monthly.

Customer Satisfaction: Complaint rate of less than 1%.

Timely Delivery: Quick and reliable shipping.

No Minimum Order Quantity: Low cost for prototypes and small runs.

Experience: Over 22 years in high-frequency PCB manufacturing.