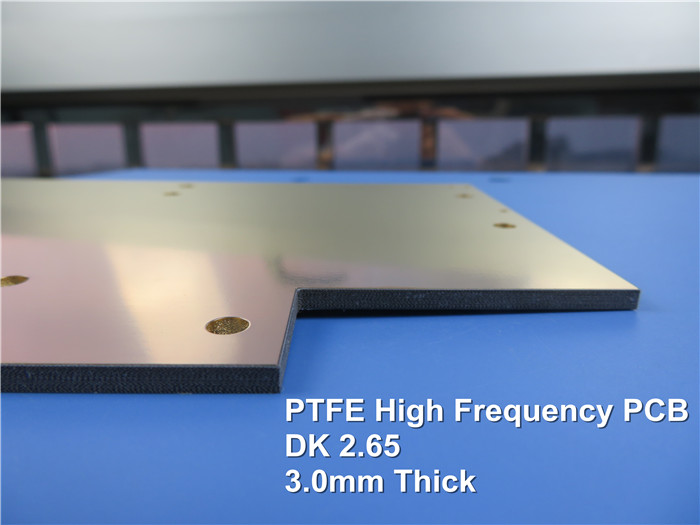

Metal Based High Frequency PCB Aluminum Based Copper Based RF PCB Immersion Gold

(Printed Circuit Boards are custom-made products, the pictures and parameters shown are just for reference)

Metal-Based High-Frequency PCB Overview

Brief Introduction

Metal-based substrates combine metal-based high-frequency materials with an intermediate layer of high-frequency materials like PTFE. One side is coated with copper foil, while the other side features either a copper or aluminum base, serving purposes such as shielding and heat dissipation. The printed circuit board (PCB) fabricated from this modified material is known as a metal-based high-frequency PCB

Wangling’s series of high-frequency materials, including F4BM, F4BME, F4BTM, F4BTME, and F4BTMS, provide options for aluminum or copper bases. Specific details are outlined in the tables below.

F4BM and F4BME Series Aluminum/Copper Substrates

F4BM and F4BME series aluminum/copper substrates |

||||||

Model |

Metal base |

Proportion |

Thermal Conductivity |

Available thicknesses of Copper or aluminum base |

Thickness tolerance of Metal base |

Availabe size |

F4BM217-AL |

Aluminum base |

2.7 |

180 W/mK |

0.48mm, 0.98mm, 1.48mm, 1.98mm, 2.98mm, 3.98mm, other thicknessnes are availabe for customization |

+0.02mm, -0.05mm |

460mm x 610mm (18"x24"), 460mm x 305mm (18"x12") |

F4BM220-AL |

||||||

F4BM233-AL |

||||||

F4BM245-AL |

||||||

F4BM255-AL |

||||||

F4BM265-AL |

||||||

F4BM275-AL |

||||||

F4BM294-AL |

||||||

F4BM300-AL |

||||||

F4BME217-AL |

||||||

F4BME220-AL |

||||||

F4BME233-AL |

||||||

F4BME245-AL |

||||||

F4BME255-AL |

||||||

F4BME265-AL |

||||||

F4BME275-AL |

||||||

F4BME294-AL |

||||||

F4BME300-AL |

||||||

F4BM217-CU |

Red copper brass |

8.9 |

380 W/mK |

|||

F4BM220-CU |

||||||

F4BM233-CU |

||||||

F4BM245-CU |

||||||

F4BM255-CU |

||||||

F4BM265-CU |

||||||

F4BM275-CU |

||||||

F4BM294-CU |

||||||

F4BM300-CU |

||||||

F4BME217-CU |

||||||

F4BME220-CU |

||||||

F4BME233-CU |

||||||

F4BME245-CU |

||||||

F4BME255-CU |

||||||

F4BME265-CU |

||||||

F4BME275-CU |

||||||

F4BME294-CU |

||||||

F4BME300-CU |

||||||

Model |

Metal base |

Proportion |

Thermal Conductivity |

Available thicknesses of Copper or aluminum base |

Thickness tolerance of Metal base |

Availabe size |

F4BTM298-AL |

Aluminum base |

2.7 |

180 W/mK |

0.48mm, 0.98mm, 1.48mm, 1.98mm, 2.98mm, 3.98mm, other thicknessnes are availabe for customization |

+0.02mm, -0.05mm |

460mm x 610mm (18"x24"), 460mm x 305mm (18"x12") |

F4BTM300-AL |

||||||

F4BTM320-AL |

||||||

F4BTM350-AL |

||||||

F4BTME298-AL |

||||||

F4BTME300-AL |

||||||

F4BTME320-AL |

||||||

F4BTME350-AL |

||||||

F4BTM298-CU |

Red copper brass |

8.9 |

380 W/mK |

|||

F4BTM300-CU |

||||||

F4BTM320-CU |

||||||

F4BTM350-CU |

||||||

F4BTME298-CU |

||||||

F4BTME300-CU |

||||||

F4BTME320-CU |

||||||

F4BTME350-CU |

||||||

F4BTMS Series Aluminum/Copper Substrates

Product Technical Parameters |

Product Models & Data Sheet |

||||||||||||

Product Features |

Test Conditions |

Unit |

F4BTMS220 |

F4BTMS233 |

F4BTMS255 |

F4BTMS265 |

F4BTMS294 |

F4BTMS300 |

F4BTMS350 |

F4BTMS430 |

F4BTMS450 |

F4BTMS615 |

F4BTMS1000 |

Dielectric Constant (Typical) |

10GHz |

/ |

2.2 |

2.33 |

2.55 |

2.65 |

2.94 |

3.00 |

3.50 |

4.30 |

4.50 |

6.15 |

10.20 |

Dielectric Constant Tolerance |

/ |

/ |

±0.02 |

±0.03 |

±0.04 |

±0.04 |

±0.04 |

±0.04 |

±0.05 |

±0.09 |

±0.09 |

±0.12 |

±0.2 |

Dielectric Constant (Design) |

10GHz |

/ |

2.2 |

2.33 |

2.55 |

2.65 |

2.94 |

3.0 |

3.50 |

4.3 |

4.5 |

6.15 |

10.2 |

Loss Tangent (Typical) |

10GHz |

/ |

0.0009 |

0.0010 |

0.0012 |

0.0012 |

0.0012 |

0.0013 |

0.0016 |

0.0015 |

0.0015 |

0.0020 |

0.0020 |

20GHz |

/ |

0.0010 |

0.0011 |

0.0013 |

0.0014 |

0.0014 |

0.0015 |

0.0019 |

0.0019 |

0.0019 |

0.0023 |

0.0023 |

|

40GHz |

/ |

0.0013 |

0.0015 |

0.0016 |

0.0018 |

0.0018 |

0.0019 |

0.0024 |

0.0024 |

0.0024 |

/ |

/ |

|

Dielectric Constant Temperature Coefficient |

-55 º~150ºC |

PPM/℃ |

-130 |

-122 |

-92 |

-88 |

-20 |

-20 |

-39 |

-60 |

-58 |

-96 |

-320 |

Peel Strength |

1 OZ RTF copper |

N/mm |

>2.4 |

>2.4 |

>1.8 |

>1.8 |

>1.2 |

>1.2 |

>1.2 |

>1.2 |

>1.2 |

>1.2 |

>1.2 |

Volume Resistivity |

Standard Condition |

MΩ.cm |

≥1×10^8 |

≥1×10^8 |

≥1×10^8 |

≥1×10^8 |

≥1×10^8 |

≥1×10^8 |

≥1×10^8 |

≥1×10^8 |

≥1×10^8 |

≥1×10^8 |

≥1×10^8 |

Surface Resistivity |

Standard Condition |

MΩ |

≥1×10^8 |

≥1×10^8 |

≥1×10^8 |

≥1×10^8 |

≥1×10^8 |

≥1×10^8 |

≥1×10^8 |

≥1×10^8 |

≥1×10^8 |

≥1×10^8 |

≥1×10^8 |

Electrical Strength (Z direction) |

5KW,500V/s |

KV/mm |

>26 |

>30 |

>32 |

>34 |

>40 |

>40 |

>42 |

>44 |

>45 |

>48 |

>23 |

Breakdown Voltage (XY direction) |

5KW,500V/s |

KV |

>35 |

>38 |

>40 |

>42 |

>48 |

>52 |

>55 |

>52 |

>54 |

>55 |

>42 |

Coefficientof Thermal Expansion (X, Y direction) |

-55 º~288ºC |

ppm/ºC |

40, 50 |

35, 40 |

15, 20 |

15, 20 |

10, 12 |

10, 11 |

10, 12 |

13, 12 |

12, 12 |

10, 12 |

16, 18 |

Coefficientof Thermal Expansion (Z direction) |

-55 º~288ºC |

ppm/ºC |

290 |

220 |

80 |

72 |

22 |

22 |

20 |

47 |

45 |

40 |

32 |

Thermal Stress |

260℃, 10s,3 times |

/ |

No delamination |

No delamination |

No delamination |

No delamination |

No delamination |

No delamination |

No delamination |

No delamination |

No delamination |

No delamination |

No delamination |

Water Absorption |

20±2℃, 24 hours |

% |

0.02 |

0.02 |

0.025 |

0.025 |

0.02 |

0.025 |

0.03 |

0.08 |

0.08 |

0.1 |

0.03 |

Density |

Room Temperature |

g/cm3 |

2.18 |

2.22 |

2.26 |

2.26 |

2.25 |

2.28 |

2.3 |

2.51 |

2.53 |

2.75 |

3.2 |

Long-Term Operating Temperature |

High-Low Temperature Chamber |

℃ |

-55~+260 |

-55~+260 |

-55~+260 |

-55~+260 |

-55~+260 |

-55~+260 |

-55~+260 |

-55~+260 |

-55~+260 |

-55~+260 |

-55~+260 |

Thermal Conductivity |

Z direction |

W/(M.K) |

0.26 |

0.28 |

0.31 |

0.36 |

0.58 |

0.58 |

0.6 |

0.63 |

0.64 |

0.67 |

0.81 |

Flammability |

/ |

UL-94 |

V-0 |

V-0 |

V-0 |

V-0 |

V-0 |

V-0 |

V-0 |

V-0 |

V-0 |

V-0 |

V-0 |

Material Composition |

/ |

/ |

PTFE,Ultra-thin and ultra-fine (quartz) fiberglass. |

PTFE,Ultra-thin and ultra-fine fiberglass, ceramics. |

|||||||||

Our PCB Capability (F4B-AL, F4B-CU)

PCB Capability (F4B**-AL / CU) |

|||

PCB Material: |

PTFE,Ultra-thin and ultra-fine fiberglass, ceramics. |

||

F4B Aluminum / Copper Base |

F4B |

DK (10GHz) |

DF (10 GHz) |

F4BM**-AL |

2.17 - 3.00 |

0.001 - 0.0018 |

|

F4BME**-AL |

2.17 - 3.00 |

0.001 - 0.0018 |

|

F4BTM**-AL |

2.98 - 3.50 |

0.0018 - 0.0025 |

|

F4BTME**-AL |

2.98 - 3.50 |

0.0018 - 0.0025 |

|

F4BTMS**-AL |

2.94 -10.2 |

0.0009-0.0022 |

|

F4BM**-CU |

2.17 - 3.00 |

0.001 - 0.0018 |

|

F4BME**-CU |

2.17 - 3.00 |

0.001 - 0.0018 |

|

F4BTM**-CU |

2.98 - 3.50 |

0.0018 - 0.0025 |

|

F4BTME**-CU |

2.98 - 3.50 |

0.0018 - 0.0025 |

|

F4BTMS**-CU |

2.94 -10.2 |

0.0009-0.0022 |

|

Layer count: |

Single Sided / Single Layer |

||

Copper weight: |

1oz (35µm), 2oz (70µm) |

||

Dielectric thickness |

0.09mm (3.5mil), 0.127mm (5mil), 0.254mm(10mil),0.508mm(20mil), 0.635mm(25mil), 0.762mm(30mil), 0.787mm(31mil), 1.016mm(40mil), 1.27mm(50mil), 1.5mm(59mil), 1.524mm(60mil), 1.575mm(62mil), 2.03mm(80mil), 2.54mm(100mil), 3.175mm(125mil), 4.6mm(160mil), 5.08mm(200mil), 6.35mm(250mil) |

||

PCB size: |

≤400mm X 500mm |

||

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

||

Surface finish: |

Bare copper, HASL, ENIG, Immersion silver, Immersion tin, OSP, Pure gold, ENEPIG etc.. |

||