Flex-Rigid 4-Layer PCB for Control Modules

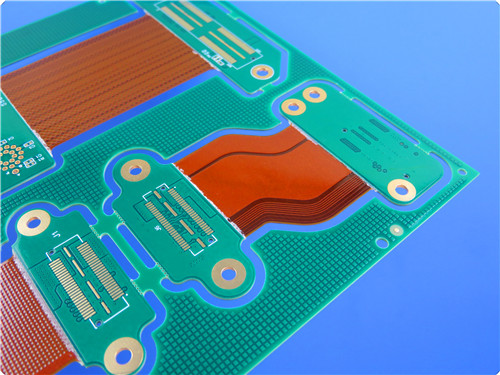

(FPC’s are custom-made products, the picture and parameters shown are just for reference)

Introducing Our 4-Layer Flex-Rigid PCB for Control Modules

We are pleased to present our cutting-edge 4-layer flex-rigid PCB, expertly crafted to merge the best features of rigid PCBs and flexible FPCs. This innovative product is specifically designed for applications requiring high-density wiring, resistance to vibration and bending, and efficient use of compact spaces.

Key Features and Benefits

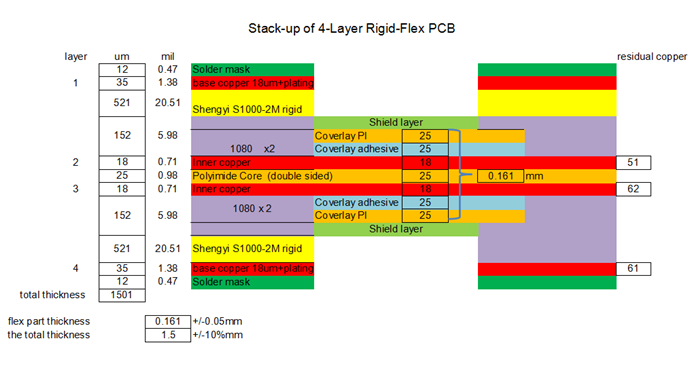

Composite Structure: Features a Tg170℃ FR-4 rigid substrate combined with a 0.16mm polyimide flexible substrate for enhanced performance.

Surface Treatment: Equipped with electroless nickel immersion gold (ENIG) for superior reliability and excellent electrical characteristics.

Thickness:Rigid PCB part: 1.50mm (finished thickness)

Flexible FPC part: 0.16mm

Copper Thickness: Utilizes 1oz (35μm) copper per layer for high current-carrying capacity.

Aesthetic and Functional Design

Solder Mask: Green solder mask enhances both functionality and visual appeal.

Silkscreen Marking: Clear white markings for easy identification.

FPC Coverlay: Yellow protective film for bend resistance and anti-oxidation.

Dimensions: Single piece size is 125.60mm × 45.60mm, with a panel design of 191.20mm × 116.60mm accommodating 3 pcs per set.

Advanced Manufacturing Techniques

Micro-Via Design: 0.2mm via diameter suitable for high-density wiring, featuring a via filling and electroplating process for a smooth surface.

Quality Assurance: 100% electrical testing (ET testing) ensures optimal conductivity and insulation, adhering to IPC-A-600 Class 2 standards.

SPCS Sheet

| Size of Rigid-FlexPCB | 191.20mm × 116.60mm=3PCS |

| Number of Layers | 4 |

| Board Type | Rigid-flex PCB |

| Board Thickness | 1.5mm |

| Board Material | FR-4 1.5mm / Polyimide 25µm |

| Board Material Supplier | Shengyi |

| Tg Value of Board Material | 60℃ |

| PTH Cu thickness | ≥20 µm |

| Inner Iayer Cu thicknes | 35 µm |

| Surface Cu thickness | 35 µm |

| Coverlay Colour | Yellow Coverlayer / Green solder mask |

| Number of Coverlay | 2 |

| Thickness of Coverlay | 25 µm |

| Stiffener Material | no |

| Stiffener Thickness | N/A |

| Type of Silkscreen Ink | IJR-4000 MW300 |

| Supplier of Silkscreen | TAIYO |

| Color of Silkscreen | White |

| Number of Silkscreen | 2 |

| Peeling test of Coverlay | No peelable |

| Legend Adhesion | 3M 90℃ No peeling after Min. 3 times test |

| Surface Finish | Immersion Gold |

| Thickness of Nickle/Gold | Au: 0.03µm(Min.); Ni 2-4µm |

| RoHS Required | Yes |

| Famability | 94-V0 |

| Thermal Shock Test | Pass, -25℃±125℃, 1000 cycles. |

| Thermal Stress | Pass, 300±5℃,10 seconds, 3 cycles. No delamination, no blistering. |

| Function | 100% Pass electrical test |

| Workmanship | Compliance with IPC-A-600H & IPC-6013C Class 2 |

Diverse Applications

Our flex-rigid PCBs are perfect for:

Consumer Electronics: Foldable screen devices, smartwatches, TWS earphones.

Industrial Equipment: Sensors for high-vibration environments, robot control modules.

Medical Instruments: Portable monitoring devices, endoscopes.

Automotive Electronics: Onboard cameras, flexible display modules.

Delivery and Customization

Standard Delivery: Each set includes 3 pcs per panel, packaged in vacuum anti-static material for protection.

Customization Options: We offer batch panelization optimization and special marking customization to meet unique requirements.