Rigid-Flex 3-Layer PCB for Wireless Security Systems

(FPC’s are custom-made products, the picture and parameters shown are just for reference)

Introducing Our 3-Layer Rigid-Flex PCB for Wireless Security Systems

We are excited to unveil our state-of-the-art 3-layer rigid-flex printed circuit board (PCB), specifically engineered for wireless security systems. With a thickness of 1.6mm at the rigid portions, this PCB is crafted from high-quality Tg170 FR-4 and polyimide materials, ensuring superior performance and reliability.

PCB Specifications

| Size of Flexible PCB | 91.5X 105.3mm |

| Number of Layers | 3 |

| Board Type | Rigid-flex PCB |

| Board Thickness | 1.6mm |

| Board Material | Polyimide (PI) 25µm +FR-4 |

| Board Material Supplier | Shengyi |

| Tg Value of Board Material | 135℃ |

| PTH Cu thickness | ≥20 µm |

| Inner Iayer Cu thicknes | 35 µm |

| Surface Cu thickness | 35 µm |

| Coverlay Colour | Yellow / Green Solder mask |

| Number of Coverlay | 2 |

| Thickness of Coverlay | 25 µm |

| Stiffener Material | NO |

| Stiffener Thickness | N/A |

| Type of Silkscreen Ink | IJR-4000 MW300 |

| Supplier of Silkscreen | TAIYO |

| Color of Silkscreen | White |

| Number of Silkscreen | 1 |

| Peeling test of Coverlay | No peelable |

| Legend Adhesion | 3M 90℃ No peeling after Min. 3 times test |

| Surface Finish | Immersion Tin |

| Thickness of Surface Finish | Tin: 0.8-1.5µm |

| RoHS Required | Yes |

| Famability | 94-V0 |

| Thermal Shock Test | Pass, -25℃±125℃, 1000 cycles. |

| Thermal Stress | Pass, 300±5℃,10 seconds, 3 cycles. No delamination, no blistering. |

| Function | 100% Pass electrical test |

| Workmanship | Compliance with IPC-A-600H & IPC-6013C Class 2 |

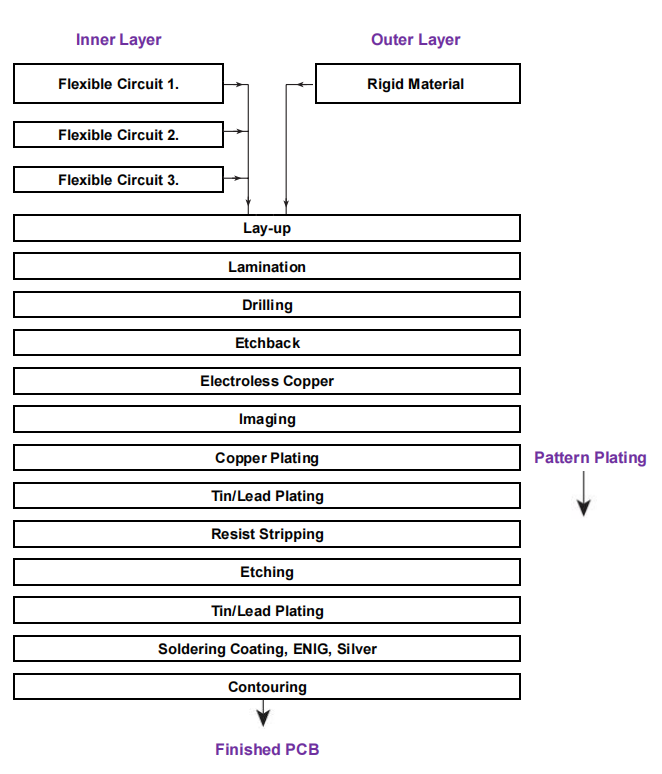

Processes

A simplified flow diagram is shown below.

Key Features and Advantages

1.Exceptional Flexibility: Our rigid-flex design offers unparalleled flexibility, making it ideal for various applications.

2.Compact Design: The innovative structure reduces overall volume, allowing for more efficient space utilization.

3.Lightweight Construction: Enjoy significant weight savings without compromising quality.

4.Enhanced Reliability: Designed for durability, our PCBs boast a high first-production yield rate of over 95%.

5.Versatile Material Options: Tailor your PCB to meet specific needs with a variety of material choices.

6.Cost-Effective Solutions: Competitive pricing without sacrificing quality or performance.

7.Streamlined Manufacturing: Benefit from a seamless processing flow managed by our experienced engineers.

Applications

Our rigid-flex PCBs are versatile and suitable for:

Laser head FPC

POS antenna soft board

Tablet keypad flex board

Understanding Multilayer Flexible Circuits

Our rigid-flex circuits are developed from traditional double-sided flexible circuits. While multilayer flexible circuits offer advantages, combining too many flexible layers may lead to complications.

Material Specifications

We utilize the following high-performance materials:

Dielectric Substrates: 50 µm (2 mil) polyimide for stability and ease of handling.

Copper Foil: 35 µm (1 oz.) copper foil for optimal current carrying capacity.

Covercoat: 25 µm (1 mil) polyimide for effective conductor encapsulation.

Bonding Materials: Sheet adhesives for reliable bonding between layers.

Why Choose Us?

With our commitment to quality and innovation, we ensure that our PCBs are not only efficient but also reliable for various applications. Explore the future of PCB technology with us!