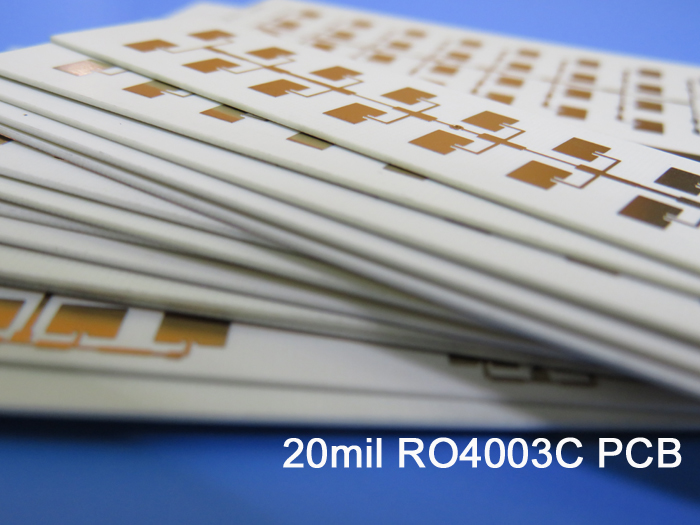

Rogers RO4003C 20mil 0.508mm Microwave PCB High-Frequency PCB for RF Applications

(Custom Printed Circuit Boards (PCBs) are tailored products; the images and specifications provided are for reference only)

RO4003C hydrocarbon ceramic laminates are specifically engineered to deliver superior high-frequency performance and cost-effective circuit fabrication. When operational frequencies reach 500 MHz and above, the variety of laminates available to designers is significantly limited.

Key Properties of RO4003C

The RO4003C material possesses essential characteristics required by designers of RF microwave circuits, matching networks, and controlled impedance transmission lines. Its low dielectric loss enables the use of RO4003C in numerous applications where conventional circuit board materials struggle due to higher operating frequencies.

Dielectric Constant Stability: The temperature coefficient of dielectric constant is among the lowest of any circuit board material, ensuring stability over a broad frequency range.

Thermal Coefficient of Expansion (CTE): The expansion coefficient of RO4003C closely matches that of copper, providing excellent dimensional stability—a crucial requirement for mixed dielectric multilayer board constructions.

The low Z-axis CTE of RO4003C ensures reliable quality in plated through holes, even under severe thermal shock conditions. Additionally, RO4003C has a glass transition temperature (Tg) exceeding 280°C, which allows its expansion characteristics to remain stable across the complete range of PCB processing temperatures.

PCB Specifications

Rogers 20mil 0.508mm RO4003C High Frequency PCB Double Sided RF PCB Repeater PA |

|

PCB SIZE |

67 x 72mm=1up |

BOARD TYPE |

Double sided PCB |

Number of Layers |

2 layers |

Surface Mount Components |

YES |

Through Hole Components |

NO |

LAYER STACKUP |

copper ------- 35um(1 oz)+plate TOP layer |

RO4003C 0.508mm |

|

copper ------- 35um(1oz) + plate BOT Layer |

|

TECHNOLOGY |

|

Minimum Trace and Space: |

7.9 mil / 5.9 mil |

Minimum / Maximum Holes: |

0.4 mm / 0.4 mm |

Number of Different Holes: |

1 |

Number of Drill Holes: |

3 |

Number of Milled Slots: |

0 |

Number of Internal Cutouts: |

0 |

Impedance Control: |

no |

Number of Gold finger: |

0 |

BOARD MATERIAL |

|

Glass Epoxy: |

RO4003C Tg280℃, er<3.48, Rogers Corp. |

Final foil external: |

1.5 oz |

Final foil internal: |

N/A |

Final height of PCB: |

0.6 mm ±0.1 |

PLATING AND COATING |

|

Surface Finish |

Immersion gold, 37% |

Solder Mask Apply To: |

N/A |

Solder Mask Color: |

N/A |

Solder Mask Type: |

N/A |

CONTOUR/CUTTING |

Routing |

MARKING |

|

Side of Component Legend |

N/A |

Colour of Component Legend |

N/A |

Manufacturer Name or Logo: |

N/A |

VIA |

Plated through hole(PTH), minimum size 0.4mm. |

FLAMIBILITY RATING |

N/A |

DIMENSION TOLERANCE |

|

Outline dimension: |

0.0059" |

Board plating: |

0.0029" |

Drill tolerance: |

0.002" |

TEST |

100% Electrical Test prior shipment |

TYPE OF ARTWORK TO BE SUPPLIED |

email file, Gerber RS-274-X, PCBDOC etc |

SERVICE AREA |

Worldwide, Globally. |

Typical Applications

.Automotive Radar and Sensors

.Cellular Base Station Antennas

.Broadcast Satellites

.Low Noise Block Converters

.Amplifiers

.RFID Technology

.png)

Data Sheet of Rogers 4003C (RO4003C)

RO4003C Typical Value |

|||||

Property |

RO4003C |

Direction |

Units |

Condition |

Test Method |

Dielectric Constant,εProcess |

3.38±0.05 |

Z |

|

10 GHz/23℃ |

IPC-TM-650 2.5.5.5 Clamped Stripline |

Dielectric Constant,εDesign |

3.55 |

Z |

|

8 to 40 GHz |

Differential Phase Length Method |

Dissipation Factortan,δ |

0.0027 |

Z |

|

10 GHz/23℃ |

IPC-TM-650 2.5.5.5 |

Thermal Coefficient of ε |

+40 |

Z |

ppm/℃ |

-50℃to 150℃ |

IPC-TM-650 2.5.5.5 |

Volume Resistivity |

1.7 x 1010 |

|

MΩ.cm |

COND A |

IPC-TM-650 2.5.17.1 |

Surface Resistivity |

4.2 x 109 |

|

MΩ |

COND A |

IPC-TM-650 2.5.17.1 |

Electrical Strength |

31.2(780) |

Z |

Kv/mm(v/mil) |

0.51mm(0.020") |

IPC-TM-650 2.5.6.2 |

Tensile Modulus |

19,650(2,850) |

X |

MPa(ksi) |

RT |

ASTM D 638 |

Tensile Strength |

139(20.2) |

X |

MPa(ksi) |

RT |

ASTM D 638 |

Flexural Strength |

276 |

|

MPa |

|

IPC-TM-650 2.4.4 |

Dimensional Stability |

<0.3 |

X,Y |

mm/m |

after etch+E2/150℃ |

IPC-TM-650 2.4.39A |

Coefficient of Thermal Expansion |

11 |

X |

ppm/℃ |

-55℃to288℃ |

IPC-TM-650 2.4.41 |

Tg |

>280 |

|

℃ TMA |

A |

IPC-TM-650 2.4.24.3 |

Td |

425 |

|

℃ TGA |

|

ASTM D 3850 |

Thermal Conductivity |

0.71 |

|

W/M/oK |

80℃ |

ASTM C518 |

Moisture Absorption |

0.06 |

|

% |

48hrs immersion 0.060" |

ASTM D 570 |

Density |

1.79 |

|

gm/cm3 |

23℃ |

ASTM D 792 |

Copper Peel Stength |

1.05 |

|

N/mm |

after solder float 1 oz. |

IPC-TM-650 2.4.8 |

Flammability |

N/A |

|

|

|

UL 94 |

Lead-free Process Compatible |

Yes |

|

|

|

|