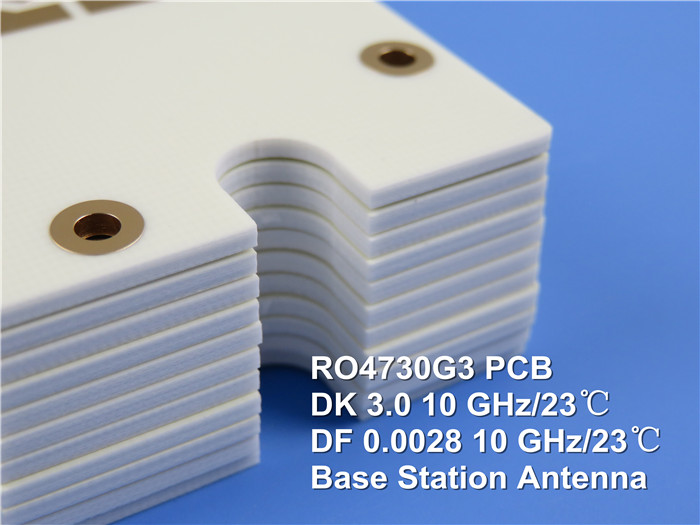

Rogers RO4730G3 Microwave PCB Board 2-Layer Rogers 4730 30mil (0.762mm) Circuit Board, DK3.0, DF 0.0028 High Frequency PCB

(Printed Circuit Boards are custom-made products; the pictures and parameters shown are for reference only.)

General Description

This double-sided RF PCB is constructed with 0.762mm (30mil) RO4730G3 material, designed specifically for wireless telecommunications antennas. The board features no solder mask on either side, and both surfaces are finished with immersion gold.

Basic Specifications

| Item | Specification |

|---|---|

| Base Material | RO4730G3, 30mil (0.762mm) |

| Dielectric Constant | 3.0 ± 0.5 |

| Layer Count | 2 Layers |

| Type | Through holes |

| Format | 110mm x 100mm (1 type = 1 piece) |

| Surface Finish | Immersion gold |

| Copper Weight | Outer layer 35 μm |

| Solder Mask / Legend | None / White |

| Final PCB Height | 1.1 mm |

| Standard | IPC 6012 Class 2 |

| Packing | 20 pieces per shipment |

| Lead Time | 7 working days |

| Shelf Life | 6 months |

.jpg)

Rogers RO4730G3 High Frequency Material

Rogers RO4730G3 antenna-grade laminates offer a reliable and cost-effective alternative to traditional PTFE-based laminates. This material possesses the essential mechanical and electrical properties required by antenna designers. The dielectric constant is 3.0, with a loss tangent of 0.0022 measured at 2.5 GHz using LoPro Reverse Treated EDC foil. These characteristics enable antenna designers to achieve significant gain while minimizing signal loss. Additionally, these materials demonstrate low Passive Intermodulation (PIM) performance, with values exceeding -160dBc.

RO4730G3 materials are compatible with standard epoxy and high-temperature lead-free solder processing. They do not require special treatments for plated through-hole preparation, unlike conventional PTFE-based laminates. Multi-layer configurations can be produced using RO4450F bondply at 175°C. The resin systems in RO4730G3 are specifically formulated to meet the demands of antenna designers. The glass transition temperature exceeds 280°C, resulting in a low Z-axis coefficient of thermal expansion (CTE), exceptional reliability for plated through holes, and suitability for lead-free solder processes.

Typical application is cellular base station antennas.

(Data Sheet of Rogers 4730 (RO4730G3))

RO4730G3 Typical Value |

|||||

Property |

RO4730G3 |

Direction |

Units |

Condition |

Test Method |

Dielectric Constant,εProcess |

3.0±0.5 |

Z |

|

10 GHz 23℃ |

IPC-TM-650 2.5.5.5 |

Dielectric Constant,εDesign |

2.98 |

Z |

|

1.7 GHz to 5 GHz |

Differential Phase Length Method |

Dissipation Factor,tanδ |

0.0028 |

Z |

|

10 GHz 23℃ |

IPC-TM-650 2.5.5.5 |

|

2.5 GHz |

||||

Thermal Coefficient of ε |

+34 |

Z |

ppm/℃ |

-50 ℃to 150℃ |

IPC-TM-650 2.5.5.5 |

Dimensional Stability |

<0.4 |

X, Y |

mm/m |

after etech +E2/150 ℃ |

IPC-TM-650 2.4.39A |

Volume Resistivity (0.030") |

9 X 107 |

|

MΩ.cm |

COND A |

IPC-TM-650 2.5.17.1 |

Surface Resistivity (0.030") |

7.2 X 105 |

|

MΩ |

COND A |

IPC-TM-650 2.5.17.1 |

PIM |

-165 |

|

dBc |

50 ohm 0.060" |

43 dBm 1900 MHz |

Electrical Strength (0.030") |

730 |

Z |

V/mil |

|

IPC-TM-650 2.5.6.2 |

Flexural Strength MD |

181 (26.3) |

|

Mpa (kpsi) |

RT |

ASTM D790 |

CMD |

139 (20.2) |

|

|||

Moisure Absorption |

0.093 |

- |

% |

48/50 |

IPC-TM-650 2.6.2.1 ASTM D570 |

Thermal Conductivity |

0.45 |

Z |

W/mK |

50℃ |

ASTM D5470 |

Coefficient of Thermal Expansion |

15.9 |

X |

ppm/℃ |

-50 ℃to 288℃ |

IPC-TM-650 2.4.4.1 |

Tg |

>280 |

|

℃ |

|

IPC-TM-650 2.4.24 |

Td |

411 |

|

℃ |

|

ASTM D3850 |

Density |

1.58 |

|

gm/cm3 |

|

ASTM D792 |

Copper Peel Stength |

4.1 |

|

pli |

1oz,LoPro EDC |

IPC-TM-650 2.4.8 |

Flammability |

V-0 |

|

|

|

UL 94 |

Lead-free Process Compatible |

Yes |

|

|

|

|