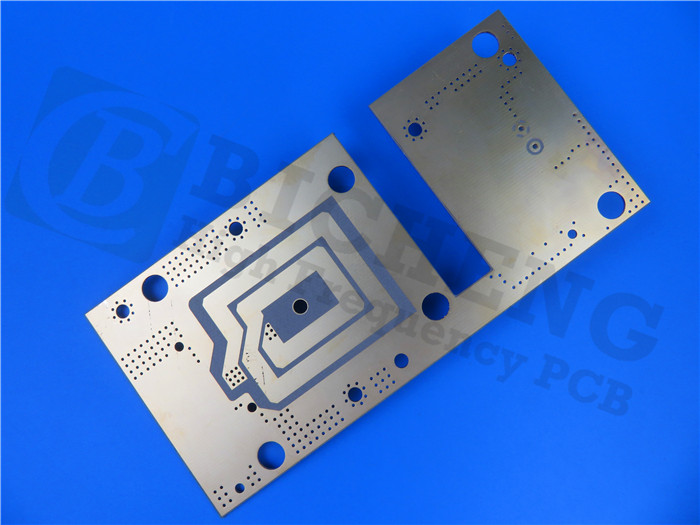

Rogers RT/duroid 6035 High Frequency PCB Built on 10mil Core With Immersion Gold for Filters

(Printed Circuit Boards are custom-made products, the picture and parameters shown are just for reference)

Product Description

RT/duroid 6035HTC high frequency circuit materials from Rogers Corporation are ceramic-filled PTFE composites specifically designed for high-power RF and microwave applications. These laminates feature superior thermal conductivity, nearly 2.4 times that of standard RT/duroid 6000 products, and are equipped with copper foil (electrodeposited and reverse treated) that offers excellent long-term thermal stability. RT/duroid 6035HTC is an exceptional choice for demanding high-power applications.

.jpg)

Features and Benefits

1.High Thermal Conductivity: Improved dielectric heat dissipation allows for lower operating temperatures in high-power applications.

2.Low Loss Tangent: Delivers excellent high-frequency performance.

3.Thermally Stable Low Profile and Reverse Treat Copper Foil: Reduces insertion loss and enhances the thermal stability of traces.

4.Advanced Filler System: Improves drillability and extends tool life compared to alumina-containing circuit materials.

Typical Applications

1.High Power RF and Microwave Amplifiers

2.Power Amplifiers, Couplers, Filters

3.Combiners, Power Dividers

PCB Capability (RT/duroid 6035HTC)

PCB Capability (RT/duroid 6035HTC) |

|

PCB Material: |

Ceramic-filled PTFE composites |

Designation: |

RT/duroid 6035HTC |

Dielectric constant: |

3.50±0.05 |

Layer count: |

Double Layer, Multilayer, Hybrid PCB |

Copper weight: |

0.5oz (17 µm), 1oz (35µm), 2oz (70µm) |

Laminate thickness: |

10mil (0.254mm), 20mil(0.508mm), 30mil (0.762mm), 60mil(1.524mm) |

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Bare copper, HASL, ENIG, Immersion silver, Immersion tin, OSP etc.. |

Data Sheet of RT/duroid 6035HTC

Property |

Typical Value RT/duroid 6035HTC |

Direction |

Unit |

Condition |

Test Method |

Dielectric Constant, εr Process |

3.50 ± 0.05 |

Z |

- |

10 GHz/23°C |

IPC-TM-650 2.5.5.5 Clamped Stripline |

Dielectric Constant, εr |

3.6 |

Z |

- |

8 GHz - 40 GHz |

Differential Phase Length Method |

Dissipation Factor, |

0.0013 |

Z |

- |

10 GHz/23°C |

IPC-TM-650, 2.5.5.5 |

Thermal Coefficient of εr |

-66 |

Z |

ppm/°C |

-50°C to 150°C |

mod IPC-TM-650, 2.5.5.5 |

Dielectric Strength |

835 |

- |

V/Mil |

15 mil thickness |

IPC-TM-650, 2.5.6.2 |

Breakdown Voltage |

12.59 |

- |

kV |

15 mil thickness |

IPC-TM-650, 2.5.6 |

Volume Resistivity |

108 |

- |

MΩ•cm |

COND A |

IPC-TM-650, 2.5.17.1 |

Surface Resistivity |

108 |

- |

MΩ |

COND A |

IPC-TM-650, 2.5.17.1 |

Tensile Modulus |

329 |

MD |

kpsi |

40 hrs @ 23°C/50RH |

ASTM D638 |

Dimensional Stability |

-0.11 |

CMD |

mm/m |

0.030” 1 oz EDC foil |

IPC-TM-650, 2.4.39A |

Coefficient of Thermal |

19 |

X |

ppm/°C |

23°C/50% RH |

IPC-TM-650 2.4.41 |

19 |

Y |

||||

39 |

Z |

||||

Thermal Conductivity |

1.44 |

- |

W/m/K |

80°C |

ASTM C518 |

Moisture Absorption |

0.06 |

- |

% |

D24/23 |

IPC-TM-650 2.6.2.1 ASTM D570 |

Density |

2.2 |

- |

gm/cm3 |

23°C |

ASTM D-792 |

Copper Peel Strength |

7.9 |

- |

pli |

20 sec.@ 288°C |

IPC-TM-650 2.4.8 |

Flammability |

V-0 |

- |

- |

- |

UL 94 |

Lead-Free Process |

YES |

|

|

|

|