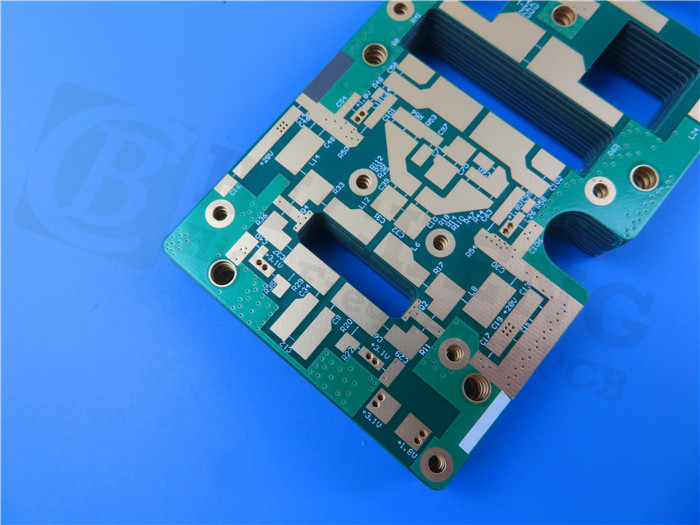

TB-73 Polyimide PCB - High-Temperature Resistant and High-Frequency PCBs for Harsh Environments

(Note: Printed Circuit Boards are custom-made products. Images and parameters are for reference only.)

Brief Introduction

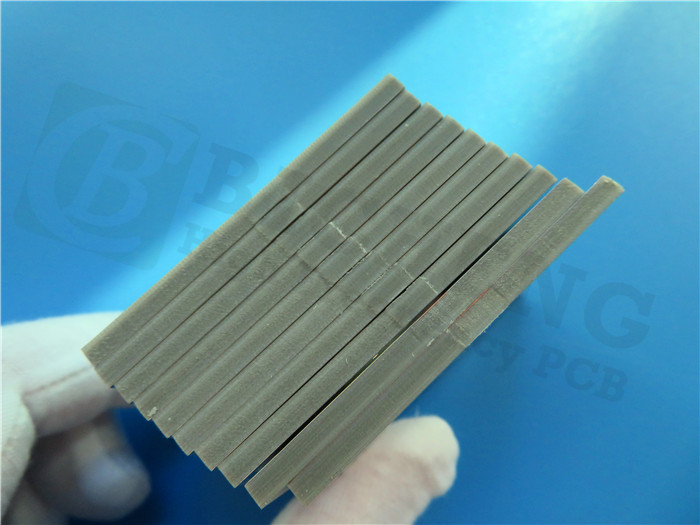

The TB-73 Polyimide PCB is a high-performance circuit board designed to withstand extreme temperatures and high-frequency conditions, making it ideal for demanding industries such as aerospace, aviation, military, and underground petroleum exploration. This material offers excellent high-frequency dielectric properties, high-temperature resistance, and radiation resistance. With a nominal thickness range of 0.1mm to 10mm, TB-73 is a reliable choice for applications requiring durability and performance in harsh environments.

Chemical Test Report

TB-73 meets the technical conditions outlined in the Q/XA50089-2004 standard. The material has undergone rigorous testing to ensure its quality and performance:

Peel Strength After Thermal Stress: ≥1.0 N/mm (Actual: 1.42 N/mm) – Pass

Peel Strength at 170℃: ≥0.7 N/mm (Actual: Pass)

Volume Resistivity: ≥5×10^6 MΩ·cm (Actual: 6.6×10^7 MΩ·cm) – Pass

Surface Resistivity: Within specified range (Actual: 3.4×10^7 MΩ and 2.3×10^8 MΩ) – Pass

Moisture Absorption Rate: ≤0.35% (Actual: 0.11%) – Pass

Breakdown Voltage: ≥40 kV (Actual: 44.3 kV) – Pass

Dielectric Constant at 1MHz: ≤4.5 (Actual: 4.12) – Pass

Dissipation Factor at 1MHz: ≤0.01 (Actual: 0.0072) – Pass

Bending Strength: ≥400 N/mm² (Machine Direction) and ≥300 N/mm² (Cross Direction) – Pass

Thermal Stress Resistance: Withstands 288℃ for 180 seconds without delamination or blistering – Pass

Glass Transition Temperature (Tg): 257℃ – Meets requirements

Our PCB Capability (TB-73 Polyimide RF PCB)

| PCB material: | Polyimide Glass Fabric Copper-clad Laminates |

| Designation: | TB-73 |

| Dielectric constant: | 4.12 |

| Layer count: | Sinlge-sided PCB, Double-sided PCB, Multi-layer PCB, Hybrid PCB |

| Dielectric thickness: | 5mil (0.127mm), 10mil(0.254mm), 20mil (0.508mm), 30mil (0.762mm), 50mil (1.27mm), 60mil (1.524mm) etc. |

| Copper weight: | 1oz (35µm), 2oz (70µm) |

| PCB size: | ≤400mm X 500mm |

| Solder mask: | Green, Black, Blue, Red, Yellow etc. |

| Surface finish: | Electroless Nickel and Immersion Gold (ENIG), HASL, Immersion silver, Immersion tin, Bare copper, OSP, ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold), Pure gold plated etc.. |

About Bicheng

Bicheng PCB is a leading supplier of high-quality printed circuit boards (PCBs) based in Shenzhen, China. Established in 2003, the company has over 20 years of experience in the industry and has built a reputation for delivering reliable and cost-effective PCB solutions to customers worldwide.

Bicheng PCB’s manufacturing capabilities cover a wide range of PCB types, including single-sided, double-sided, and multilayer boards, with layer counts ranging from 1 to 32. The company’s PCBs are used in various industries, including telecommunications, aerospace, defense, medical, and industrial electronics.

Bicheng PCB offers a wide range of substrate materials, including high-frequency materials such as RO4003C, RO4350B, and RO4730G3, as well as standard FR-4 materials like high-Tg S1000-2M, TU-872 SLK, TU-768, IT-180A, and Isola 370HR. The company also provides metal core, polyimide, and PET substrates, among others.

Advanced Manufacturing Capabilities:

Board Size: Up to 1100mm x 600mm

Board Outline Tolerance: ±0.0059" (0.15mm)

Thickness Tolerance: ±8% for T≥0.8mm and ±10% for T<0.8mm

Copper Thickness: 17µm to 350µm (0.5oz to 10oz)

Drill Hole Diameter: 0.0079" to 0.25" (0.2mm to 6.35mm)

Bicheng PCB is committed to quality and customer satisfaction, as reflected in its ISO 9001:2015 certification. The company’s experienced engineers and technicians work closely with customers to ensure their specific requirements are met, delivering PCBs on time and within budget.

Appendix: Data Sheet (TB-73 Laminates)

| Material Information | |

|---|---|

| Material Name | Copper-clad polyimide glass fabric laminates (TB-73) |

| Date | 2022.5.22 |

| Specifications | 1240×630×0.5mm 1/1 |

| Technical Conditions | Q/XA50089-2004 |

| No. | Item | Processing Condition | Standard Specification | Test Results | Conclusion |

|---|---|---|---|---|---|

| 1 | Peel Strength (N/mm) | After Thermal Stress | ≥1.0 | 1.42 | Pass |

| 170℃ | ≥0.7 | Pass | Pass | ||

| After Process Solution | ≥0.95 | 1.13 | Pass | ||

| 2 | Volume Resistivity (MΩ·cm) | C-96/35/90 | ≥5×10^6 | 6.6×10^7 | Pass |

| E-24/204 | ≥5×10^6 | 6.2×10^8 | Pass | ||

| 3 | Surface Resistivity (MΩ) | C-96/35/90 | ≥1×10^6 | 3.4×10^7 | Pass |

| E-24/204 | ≥1×10^6 | 2.3×10^8 | Pass | ||

| 4 | Moisture Absorption Rate (%) | D-24/23 | ≤0.35% | 0.11 | Pass |

| 5 | Breakdown Voltage (kV) | D-48/50 + D-0.5/23 | ≥40 kV | 44.3 | Pass |

| 6 | Dielectric Constant at 1MHz | As Received | ≤4.5 | 4.12 | Pass |

| 7 | Dissipation Factor at 1MHz | As Received | ≤0.01 | 0.0072 | Pass |

| 8 | Bending Strength | Machine Direction | ≥400 N/mm² | 410.2 | Pass |

| Cross Direction | ≥300 N/mm² | 355.1 | Pass | ||

| 9 | Thermal Stress (288℃) | As Received | 180s, no delamination, no blistering | Pass | Pass |

| 10 | Glass Transition Temperature (Tg Value) | As Received | 257℃ | Pass | Pass |